- Home >

- Products >

- Tool Correction System / for Special-purpose Machine >

- Cylinder Boring Head

PRODUCTS

Tool Correction System / for Special-purpose Machine

Cylinder Boring Head

Product Outline

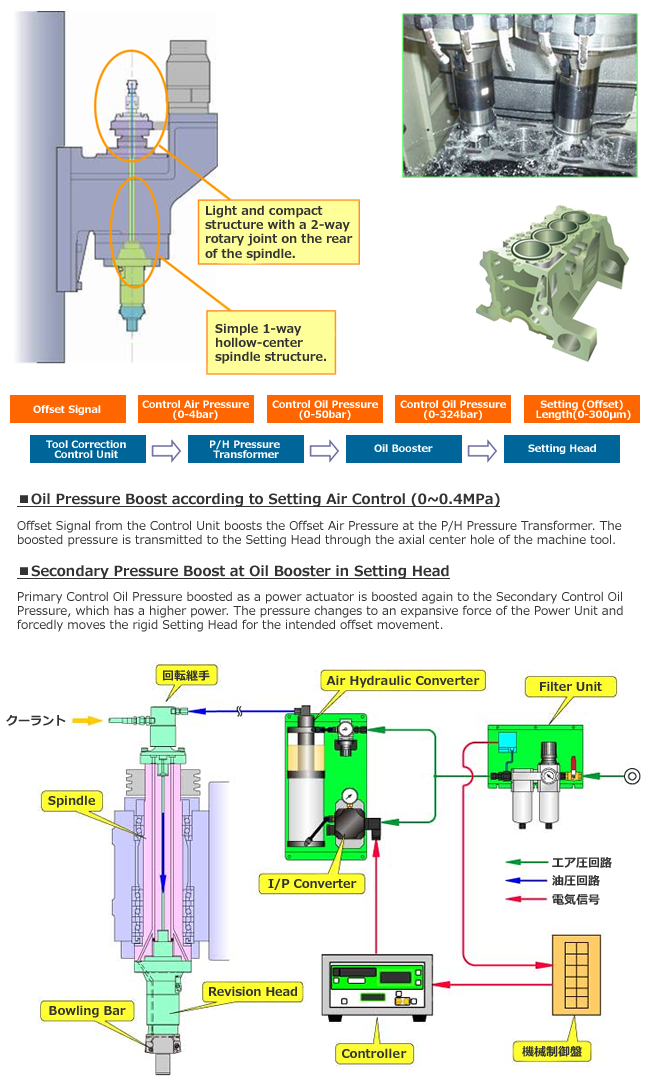

Downsized elastically-deformable design to keep high rigidity for deep hole processing. Minimal-length Setting Head. High productivity in high processing and high precision are on the same vector.

Product Features

- Downsized design of the proven Radial Setting Head.

- Reciprocating processing, i.e. push-processing in retraction mode or pull-processing in offset mode is possible.

- Both Finish and Semi-finish processing available with one holder. Highly precise processing with less influence from heat deformation and residual stress is provided by 4-pass processing.

- The tip part is a rigid structure, which makes the high frequency vibration characteristics better and contributes to the longer tool life.

- In combination with the vibration analysis we’re proud of, we can offer the best processing condition for realization of high precision.

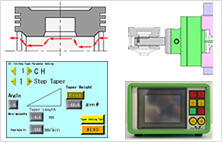

Schema

Products List

The basic item of the Tool Correction System for the finish boring process. This product made a great achievement in the past few decades with the high reliability.

For high-speed processing and downsizing of machine, newly developed elastically-deformable design based on a different concept from Radial Setting Head

Downsized elastically-deformable design to keep high rigidity for deep hole processing. Minimal-length Setting Head.

Developed for lathe processing, in which workpiece is rotated, based on the Radial Setting Head type elastically-deformable design, highly reliable for boring process.