- Home >

- New products >

- ATC Tool Correction System NTE-ζseries >

- NTEζ-1Push- Button ATC Setting Head

NEW PRODUCTS

ATC Tool Correction System NTE-ζseries

NTEζ-1Push- Button ATC Setting Head

[1Push=1μm(φ2μm)] Just Press Buttons to Operate

Just pushing buttons is the way to operate this Setting Head. Our product concept of “easy operation” has

never been changed for the past 30 years, regardless of the shift in control unit from analogue to digital.

The new NTE ζ- 1 ATC Setting Head was developed in combination of a new design concept and conventional

easy-operation of push button method.

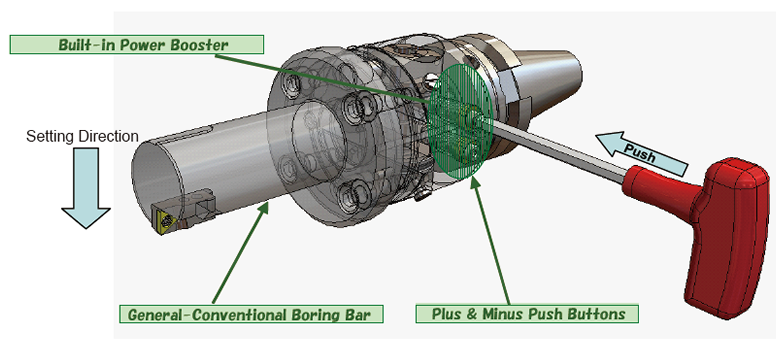

Tool correction is made by just pushing the buttons on the side of the Setting Head. The offset made by one

push is 1μm (φ2μm). This 1-push = 1μm accuracy is our fundamental idea remaining unchanged. Both Plus

and Minus Tool Corrections are available through pressing the buttons by just a light force of 3~4Kg with a

wrench (Allen Key). For example, to make a correction of φ6μm, you just press the button three times.

That’s all you need to operate the Setting Head. This easy operation is one of the features of this product.

Quick-Reaction Hydraulic Booster

Setting movement (Tool Correction movement) is made by our unique hydraulic booster, which offers significantly high accuracy and responsiveness. With the hydraulic booster, quick reaction, so-called “brisk and smooth setting reaction” is available. The shift of setting movement is precise at micron level. In addition, the shifted position is steadily kept by the robust lock mechanism.

Solid, Compact and Rigid Design

Elastic part tiltable from the axial center is incorporated into the solid-structure housing. Due to the solidity, this Setting Head has both tiltable spring property and robust rigidity against other directional movement.

For Both Manual and Automatic Operations

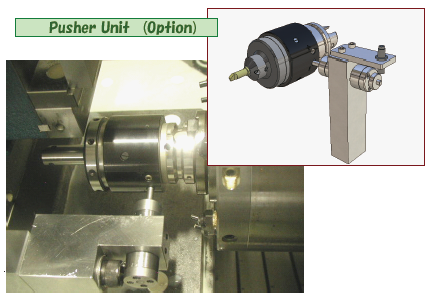

Regardless of tool presetting outside the machine or manual adjustment inside the machine, tool correction adjustment can be made by just pushing the plus/minus button with a wrench (Allen Key). As an increment/ decrement by one push is 1μm, setting adjustment can be done easily without using dial gauge to check the setting length. Due to the easy operation, machine downtime for setting adjustment is minimized so that the machine operation ratio can be effectively increased. In automatic tool correction, a pusher unit can be used by installing it to the machine table or jig. The Setting Head is moved to the target position and pressed toward the pusher unit at the designated times of operation in response to the machine program. The pusher unit has a recoil structure for fail-safe.

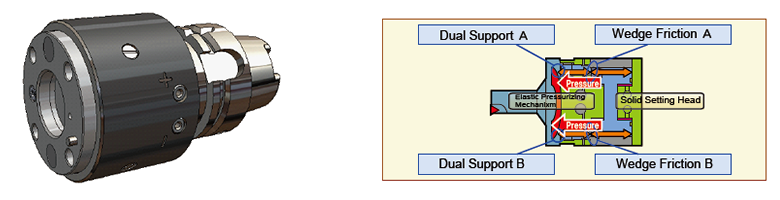

Dual Wedge Support with High Damping Ratio

This Setting Head consists of a solid housing and a rigid pressurizing mechanism, which is a parallel annular-formed elastic structure. Due to this design, cutting force to the tip is triangularly received well by the dual support A and B allocated on the both ends of the pressurizing part . In addition, the wedge friction A and B functioning coordinately has high damping ratio to suppress the self-excited vibration. The damping ratio is high of ζ=6% in measurement at out machinig center.

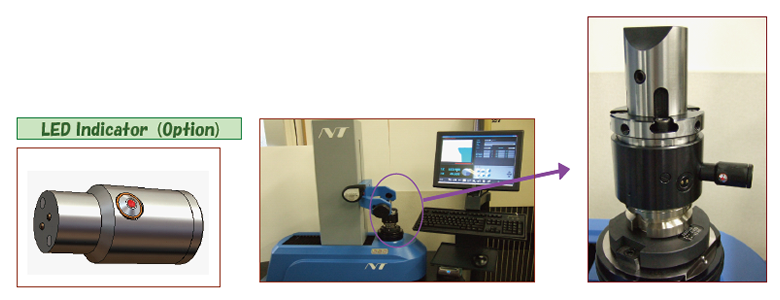

Precise Zero-position Indication with LED Indicator for Easy Preset

Tool preset can also be easily completed by just checking the diameter of tip edge and pushing the plus/minus button. In addition, without locking the setting position, the Setting Head are ready to use just after the presetting. To confirm Zero-position, a removable LED indicator is available . When it is attached to the zero-set contact on the Setting Head and the Setting Head turns into Zero-position, the LED indicator lamp is lit on. The precise Zero position can be confirmed in such a easy way.