- Home >

- New Products >

- ATC Tool Correction System NTE-ζseries >

- NTEζ-2 Push-Button ATC Setting Head

NEW PRODUCTS

ATC Tool Correction System NTE-ζseries

NTEζ-2 Push-Button ATC Setting Head

Micron-level operation is performed by just pushing buttons

Just pushing buttons is the new way of operating the New Tool Correction System.

The core concept of easy operation has never changed for the past 30 years.This operation method has been the same regardless of the shift from Analogue to Digital Controllers.

The new NTE ζ-2 ATC Setting Head was created by combining a new technology with the core concept of easy operation.

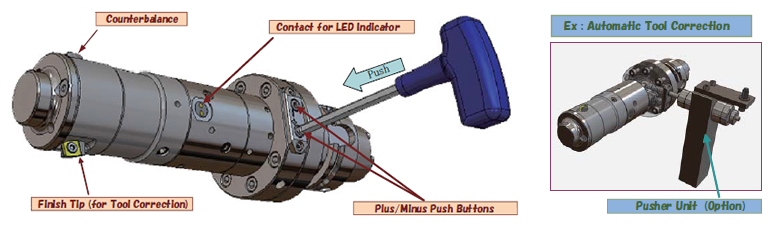

Tool Correction is made by just pushing the buttons on the side of the Setting Head.

The correction length is made at micron level.

Both Plus and Minus Tool Corrections are avaiable through pressing the buttons by just a light force of 3~4Kg with a wrench (Allen Key).

For example, to make a tool correction of φ6μm, you just need to press the button three times.

This easy operation is the basic feature of this product.

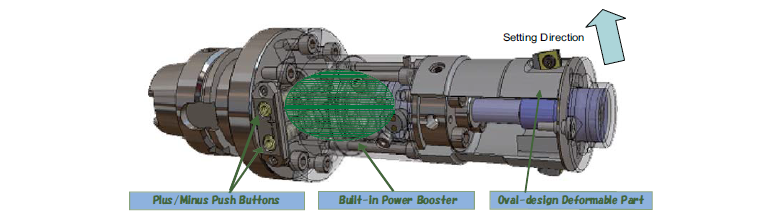

Quick-Reaction Hydraulic Booster

Setting movement (Tool Correction) is made by our unique Hydraulic Booster, which offers significantly high accuracy and quick response. With the Hydraulic Booster, quick reaction, and so-called "brisk and smooth setting reaction" is obtainable. The shift of setting movement is precise at micron level. In addition, the shifted position is also precisely kept in place by the robust lock mechanism.

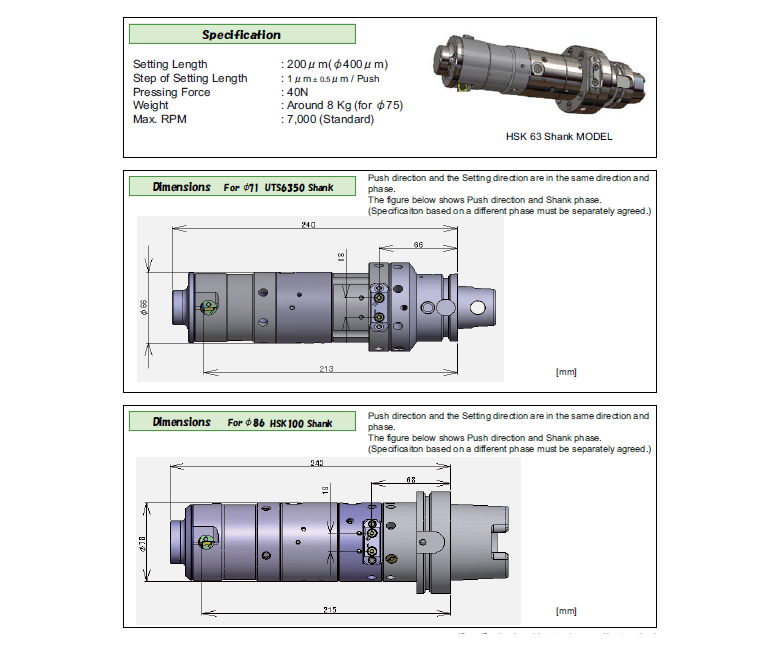

Oval Setting Head for High Speed Bylinder Boring

This Setting Head performs tool correction by deforming its top end into an oval shape. As the deformable part is firmly supported by the back-up structure, this Setting Head has high rigidity and high damping ratio. Thus, it offers high stability even for speeds in the region of 7,000 RPM. Cartridge for Finish tip and a Dummy Cartridge for counterbalance move to same length but in opposite direction during the setting movement thereby balancing this Setting Head for High Speed Boring.

For Both Manual and Automatic Operations

Regardless of the presetting outside the machine or manual adjustment inside the machine, tool correction adjustment is made only by just pushing the plus/minus button with a wrench (Allen Key).As an increment / decrement by one push is 1μm(φ2μm), setting adjustment can be done easily without using dial gauge to check the setting length. This easiness minimizes the machine downtime for diameter adjustment so that the machine operation ratio is increased. For Automatic Tool Correction, a Pusher Unit can be installed to the machine table or jig. Through the machine program, the Setting Head can be moved to a target setting position and pressed toward the Actuator Unit at designated frequency. The Pusher Unit has a recoil structure for fail safe functioning.

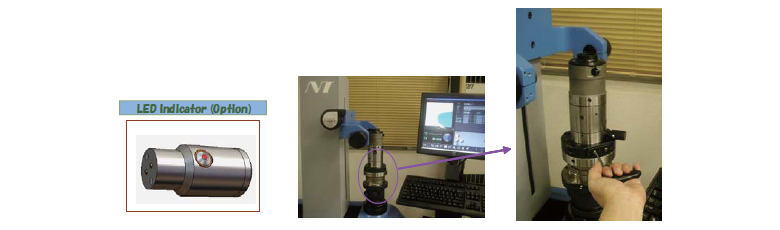

Precise Zero-Position Indication with LED Indicator

Tool presetting is also easily completed by measuring the diameter at the Cutting Tip and pushing the Plus/Minus button to achieve the required Dia.

In addition, without any locking operation for the setting position, the Setting Head can be used right after the present.

When the LED Indicator is attached to the zero-set contact on the Setting Head and the Setting Head becomes Zero-position mode, LED indicator lamp is lit on.

The precise Zero position can therefore be confirmed easily.